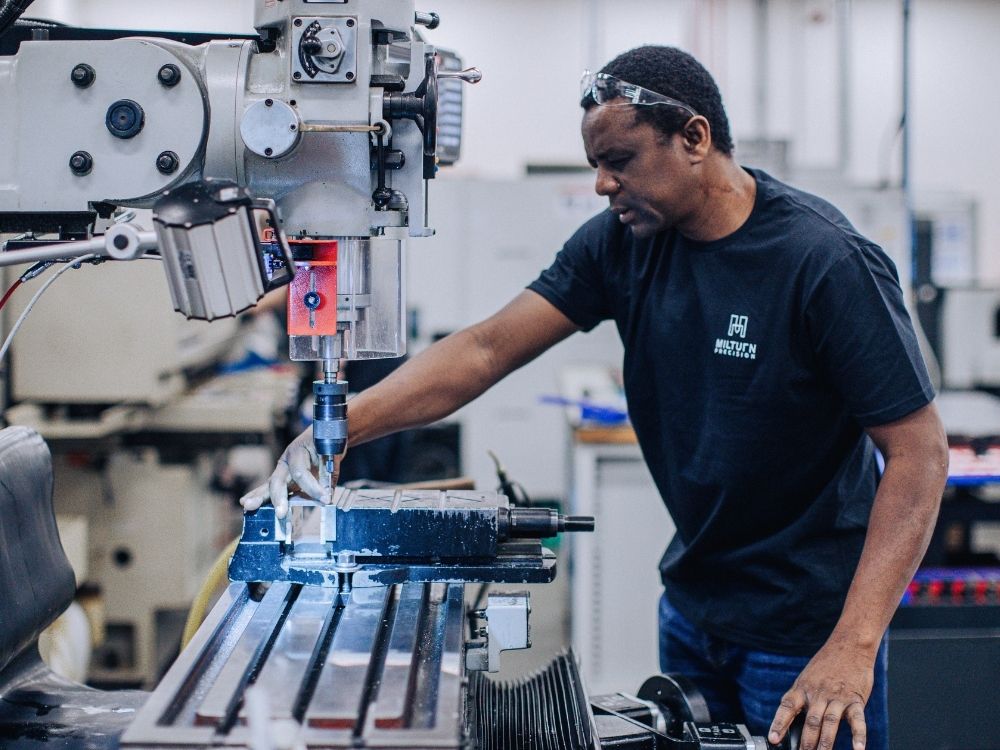

Defence component manufacturing

A major defence systems supplier chose Milturn to support a new reconnaissance, surveillance and targeting programme. The system protects military personnel and supports homeland security work, so accuracy and reliability are essential. The customer needed a machining partner that could take responsibility for machining, finishing and laser engraving in one controlled route. They also wanted capability suited to defence applications across land and air platforms.

Precision engineering for the defence sector

The programme included complex aluminium and stainless components with tight tolerances and defined surface standards. These parts sit inside safety-critical systems where durability, performance and long-term stability matter. Lead times were short, so the customer needed a supplier with the capability to deliver consistent results at scale. Any variation risked delays to system build, test and integration.

Defence component manufacturing without supply chain fragmentation

Defence programmes operate under strict quality expectations. Components must perform under pressure and withstand extreme conditions. Quality assurance is key, as parts often sit inside targeting systems, sensor units or protected assemblies on military vehicles and aerospace platforms. Long approval cycles and detailed compliance checks mean procurement teams look for suppliers who can deliver steady, repeatable batches.

A single route for machining, finishing and marking reduces supply chain risk. It avoids the variation that comes from juggling separate vendors and keeps manufacturing processes aligned for defence industry standards.

A complete route built for defence industry requirements

Milturn set up an in-house route that covers machining, finishing and marking from start to finish. Support included:

- Multi-axis precision engineering for complex features

- In-house finishing for corrosion resistance and visual consistency

- Laser engraving aligned to marking requirements for weapons-adjacent systems and safety systems

- Checks at each stage to manage variation across batches

- Scheduling that supports the customer’s production plan

Each step sits within a documented process route. This gives the customer confidence that the same results arrive every batch, even when demand scales up across multiple builds.

Capability suited to defence applications

The defence industry relies on durable components that support mobility, protection and operation in harsh environments. These systems must function across land, air and maritime platforms, including armoured vehicles and specialised electronics used on naval vessels. Precision matters throughout. Parts must withstand vibration, temperature changes and operational pressure without loss of performance.

Milturn’s capability fits these requirements. Our machining, finishing and marking route supports projects where reliability is paramount and where manufacturing processes must stay controlled for long-term repeatability.

A trusted partner for time-critical defence builds

The programme now receives components that meet tolerance, finish and marking standards on repeat. Parts move straight into assembly with no rework. This improves flow, reduces inspection time and supports the customer’s build and test schedule.

Milturn continues to support a broad range of defence projects and is ready to discuss new work that needs controlled machining, stable processes and reliable supply for UK defence programmes.

If you’re looking for a precision engineering partner who understands the challenges of UK and EU defence programmes, speak to our team today.