Hard Anodising

Hard anodising is an electrolytic process for aluminium that provides superior protection and outstanding corrosion resistance.

- Superior Corrosion Resistance

- Precise Coating Control

- Versatile Colour Options

The process creates a clear finish on the part, and when sealed, it enhances durability and extends functionality even further.

The process uses a higher concentration of sulphuric acid compared to soft anodising, along with chilled temperatures and higher voltage. This creates a thin layer of aluminium oxide under controlled conditions, with the thickness measurable using XRF equipment. While sulphuric anodising can be used for a variety of purposes, it is primarily applied for decorative finishes that require a certain level of corrosion resistance. Hard anodising typically produces a coating between 25-50 µm, with thicker coatings offering greater corrosion resistance. In addition to clear anodising, we offer a range of colours, including black. The final colour is influenced by the material grade and composition.

Material Suitability

We specialise in anodising aluminium, primarily 6000 and 7000 grades. Material composition significantly impacts results, so grade suitability should be checked, typically at the design phase using the material’s datasheet.

Anodising Standards

We adhere to anodising standards, including BS ISO 7599, as well as other specific requirements from our customers. Please contact us if you would like to discuss any particular needs or specifications.

Expert Surface Conditioning

Our advanced surface conditioning processes, including precise masking, vapour blasting, and etching, ensure your parts are perfectly prepared for anodising, guaranteeing high-quality and flawless finishes every time.

Surface conditioning

At Milturn Finishing’s new facility, we offer a variety of surface conditioning processes:

- Masking: We use precise masking to protect areas of the part that don’t require anodising, allowing only the desired sections to be treated.

- Vapour Blasting: Vapour blasting (or aqua blasting) can be a standalone service or combined with anodising. It uses air, water, and abrasive media to achieve a smooth finish while preserving part dimensions.

- Pre-treatment / Etching: Etching removes contaminants and oxides, ensuring the part is ready for anodising.

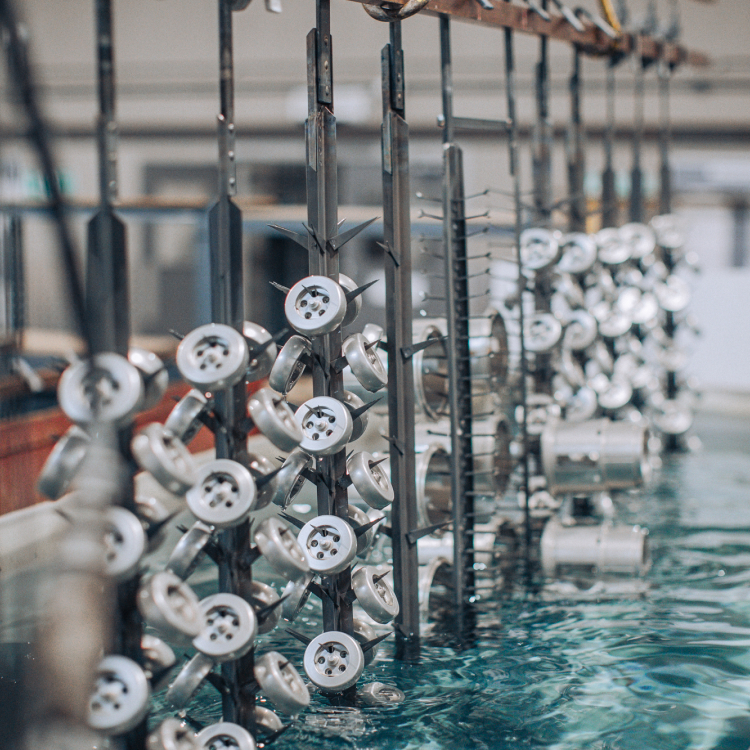

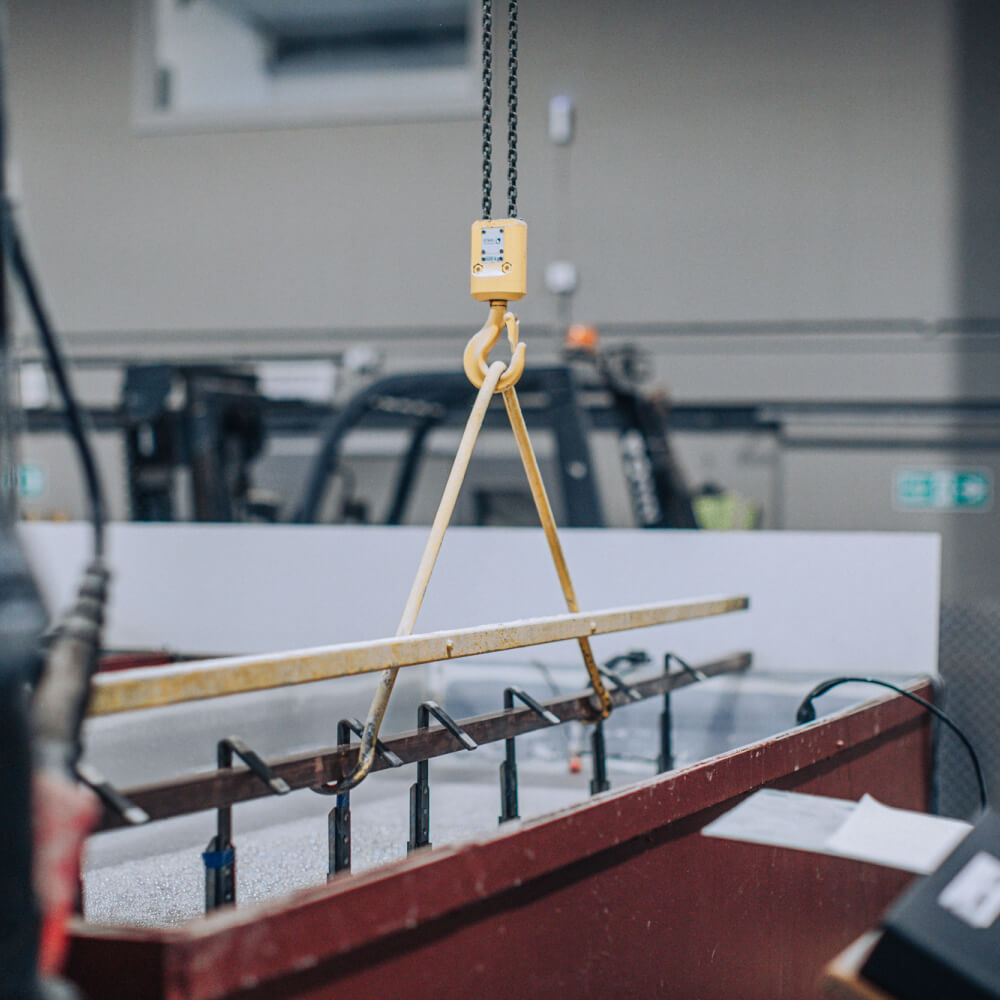

Jigs

A key part of anodising is securing parts in jigs to maintain electrical contact. We offer a range of jigs and can design custom solutions if needed. To avoid visible jigging marks on decorative surfaces, additional features may be required in the component design. We recommend including any jigging requirements on the part’s drawing for optimal results.

Colour Dyes

In addition to clear anodising, we offer a variety of anodising colours, with black and red being the most popular. Colour consistency can be affected by the material grade. Although we have over 20 years of experience working with colour dyes, exact colour matching between batches cannot always be guaranteed. We aim to achieve consistent colour matching within pre-agreed tolerances.

Gallery

FAQ's

Explore our FAQs to find answers to common inquiries. If you need more information, our team is here to help, please don’t hesitate to get in touch.

Hard anodising is an electrolytic process specifically for aluminium that creates a thicker aluminium oxide layer (25-50 µm) compared to sulphuric anodising. This thicker coating offers superior corrosion resistance and enhanced durability, making it ideal for applications requiring robust protection. Additionally, this process anodising uses higher concentrations of sulphuric acid, chilled temperatures, and increased voltage to achieve these superior properties.

At Milturn, we specialise in anodising aluminium primarily in the 6000 and 7000 grades. These grades are well-suited for this type of anodising due to their excellent mechanical properties and composition. It is important to verify the material’s suitability during the design phase by consulting the relevant datasheets or contacting us directly to ensure optimal resul

We offer a variety of colour options with anodising, including clear, black, and red finishes. The final colour can be influenced by the aluminium grade and composition. While we strive for consistent colour matching within pre-agreed tolerances, exact matches between batches may vary slightly. Our extensive experience with colour dyes ensures that your requirements are met with high precision and aesthetic appeal.

Get in touch to discuss your project today

At Milturn, we deliver precision machining tailored to your needs. Contact us to start your project with a trusted partner.

Get a quote 01530 648 400Quotation Approval

Receive a clear and competitive quote quickly. We ensure transparency to help you make informed decisions.

Project Management

Our dedicated team oversees every stage, ensuring smooth communication and timely progress.

Guaranteed Delivery

Count on us for prompt and reliable delivery, maintaining quality and meeting your deadlines.