CNC Milling

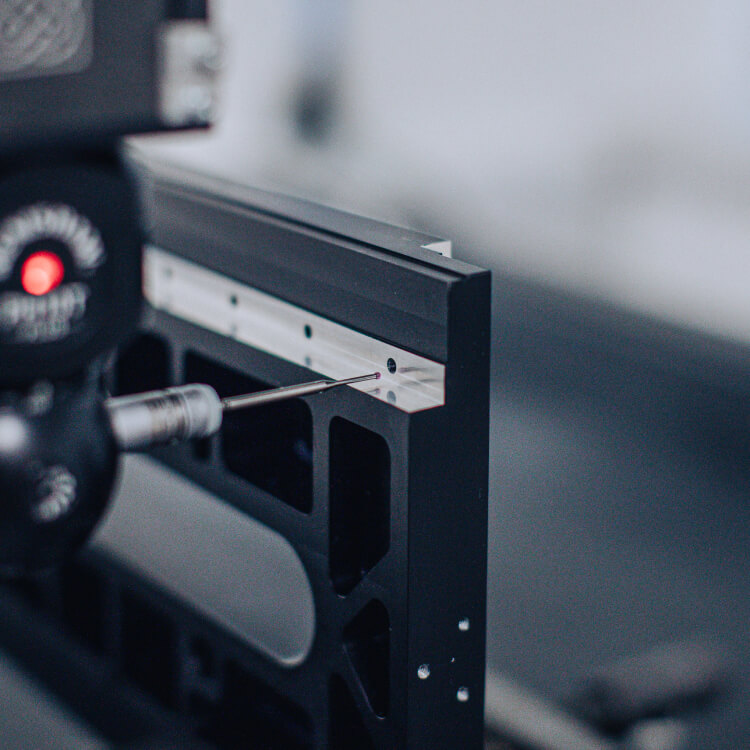

Our advanced machine shop is equipped with modern CNC and manual capabilities, delivering precision manufacturing for high-quality components and versatile production needs.

- Comprehensive Capabilities

- Prototyping and Small Batches

- Attention to Detail

Innovative and Efficient Subcontract Manufacturing Solutions.

Milturn is committed to driving innovation and quality in manufacturing while minimising costs and waste. Our capabilities encompass CNC and manual milling and turning, all supported by advanced quality control facilities to ensure precision. We specialise in prototyping and small-batch production through our dedicated tool room, staffed by skilled toolmakers. With meticulous attention to detail and industry-leading processes, we deliver components of the highest standards.

End-to-End Solutions

We handle every stage of the manufacturing process, from concept and design to full-scale production.

Focus on Efficiency

Our corporate policy prioritises reducing waste and optimising cost efficiency in all manufacturing processes.

Commitment to Quality

We ensure superior results through innovative design and precision engineering practices.

Quality, Performance, and Value

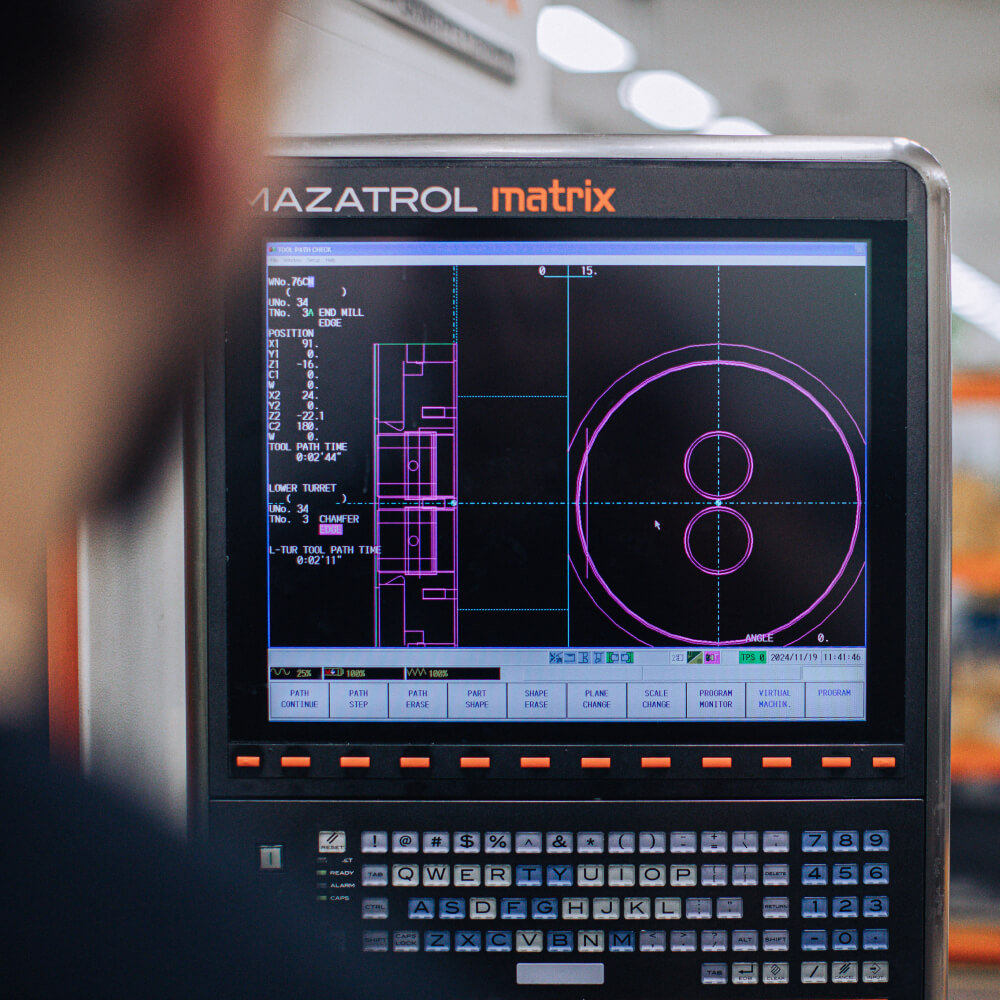

Our highly skilled team utilises a range of CAD/CAM software to meticulously review and refine your designs, ensuring they meet all necessary checks before moving into production. This guarantees that manufacturing is carried out to the highest standards.

From small to large components, every product is created within a robust quality management system, ensuring consistent results, minimised waste, and reliable repeatability.

Materials We Work With.

Our machine shop specialises in machining a diverse range of materials, ensuring flexibility and precision for various applications:

- Metals: Aluminium, brass, cast iron, cast steel, machining steel, and copper/copper alloys.

- Heat-Treated Steels: Case-hardened and heat-treated steel for enhanced durability.

- Stainless Steels: Including V2A, V4A, acid-resistant, and other stainless grades.

- Plastics: Delrin 100 and high-performance plastics for lightweight and specialised applications.

This wide material expertise allows us to meet your unique manufacturing requirements with precision and quality.

CNC Milling FAQ's

Explore our FAQs to find answers to common inquiries. If you need more information, our team is here to help, please don’t hesitate to get in touch.

Milturn offers a comprehensive range of CNC Milling services, from precise prototyping to small-batch and large-scale production. We utilise advanced CNC and manual milling equipment, supported by modern CAD/CAM software, to deliver high-quality components. Our state-of-the-art machinery ensures accuracy and versatility, enabling us to handle complex geometries and varied production requirements efficiently.

Milturn guarantees quality and efficiency through several key practices:

End-to-End Solutions: Managing every stage from concept and design to full-scale production ensures consistency and precision.

Advanced Quality Control: Our robust quality management system minimises waste and ensures reliable repeatability.

Skilled Team: Experienced toolmakers and engineers use sophisticated CAD/CAM software to refine designs before production.

Focus on Efficiency: We prioritise reducing waste and optimising costs, ensuring timely delivery without compromising on standards.

These measures ensure that Milturn delivers superior results efficiently and cost-effectively.

Milturn is equipped to manage a wide variety of CNC Milling projects, including:

Prototyping: Perfect for testing and development with high precision and quick turnaround.

Small Batches: Ideal for specialised or limited-run productions without sacrificing quality.

Large-Scale Production: Suitable for mass manufacturing with consistent quality and efficiency.

Custom Components: Tailored solutions for complex and unique geometries across various industries such as automotive, aerospace, and medical devices.

Our versatile CNC Milling capabilities ensure that whether your project is small or large, simple or complex, Milturn can deliver exceptional results.

Gallery

CNC Milling Capabilities

Get in touch to discuss your project today

At Milturn, we deliver precision machining tailored to your needs. Contact us to start your project with a trusted partner.

Get a quote 01530 648 400Quotation Approval

Receive a clear and competitive quote quickly. We ensure transparency to help you make informed decisions.

Project Management

Our dedicated team oversees every stage, ensuring smooth communication and timely progress.

Guaranteed Delivery

Count on us for prompt and reliable delivery, maintaining quality and meeting your deadlines.